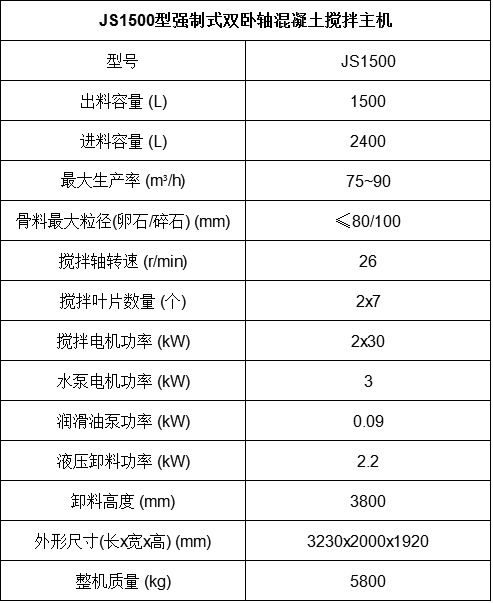

Double sleeper shaft stirring host:

Host 1, and double shaft mixer is according to the design and manufacture GB9142-2000, adopts forced mixing method, for the harsh, half dry rigid, plastic and all kinds of proportioning of concrete can in the shortest possible time to fully mixing, meet the requirements of the use of different working conditions.

2, to adapt to different working conditions and the requirements of the aggregate particle size, stirring arm can do on axis 45 °, 60 °, 90 °, 120 ° and 180 °.

3. The discharge opening can be adjusted according to the need of hydraulic door unloading machine. The special manual quick unloading function can remove the concrete in the mixer during the sudden stop.

4. Lubrication of independent lubrication pump.

Dual-axial concrete mixer is my company application of advanced technology and scientific research at home and abroad, combined with our company for many years production experience of concrete mixer, designed a new type of dual-axial concrete mixer, is the ideal dual-axial mixing model. Applicable to all kinds of large and medium-sized prefabricated file and roads, Bridges, water conservancy, port and other industrial and civil building engineering, and can be dry mixing concrete, plastic concrete, liquidity concrete, lightweight aggregate concrete and mortar, mortar, is an efficient model, application is very broad.

This series of products the whole machine design reasonable structure, high mixing efficiency, mixing of good quality, easy to clean, high efficiency, low energy consumption, the layout is novel, high degree of automation, convenient operation and maintenance, is the ideal of concrete mixing equipment.

The planet-type speed reducer adopts internationally well-known brand components, which has high transmission efficiency and stable performance, which greatly reduces the failure rate of the equipment and increases the utilization rate of the equipment.

Unique design of shaft end bearing and seal bearing support and its seal separation, a variety of shaft end seal protection, makes the bearing seal is reliable, greatly improve the service life of the host, no worries.

Hydraulic door unloading mechanism can adjust discharge opening according to the need, there are three stop and manual opening device.

Equipped with special electric lubricating oil pump, the only four independent pump core can be supplied directly to the four axles, and no shunt valve should be used.